Quick Service Management

Project Details

| Client: | A distinguished Quick Service Management Restaurant |

| Pricing: | Hourly Pricing |

| Duration: | 6 Months (Initial Results) |

| Staff: | 1 Team Lead, 1 Senior Developer and 3 Junior Developers |

| Technologies: | Python 3x, Django, Fast API, C/C++, Redis, Elasticsearch 7x, MySQL, Microsoft Azure, Weka, Angular, Android Studio, IOT, Nvidia Jetson Nano, OpenCV, YOLO, Arduino Uno |

| Services: | AI, ML, Deep Learning, App Development, Computer Vision, Workplace Automation |

Quick Service Restaurant managed to Transform their whole business with the Magic of Machine Learning and Artificial Intelligence.

See how a simple QSR boosted their Service speed, reduce wastage, drove Sales and improved their employee and customer satisfaction astonishingly when they partnered with Hitech Provider.

SUMMARY

Hitech-provider trained the data based on the suite of sensors they have implemented in their Kitchen, lobby and in drive thru. By measuring the number of customers entering the restaurant and, in the drive-through, Hitech Provider trained the data through complex Algorithms of Machine Learning and Artificial intelligence models and successfully managed to predict the number of burgers, fries, chicken and Salads required in the given time of day. The required demand was then passed with cooking instructions to kitchen staff with the help of our mobile application. By doing this the efficiency of Kitchen Staff has been improved significantly, the customer waiting time have been cut down to 50% and the companies Stockout problems has resolved.

THE CLIENT

The Client was a large QSR with locations throughout the world. They serve burgers, fries, chicken, and breakfast items on their location. This is the Case study which tells you about the transformation of their single restaurant which serves about 3000 customers daily and they operate 24/7.

CHALLENGES

The issues with our Client are same as most of QSRs are facing, Slow service times in the drive-thru and in lobby, also in Covid the more people ordering in drive thru which makes the condition more troublesome. We discussed with their whole team and even their CEO on what location they want to target because although their locations are very optimized and they do not afraid change but as you all know Machine Learning and Artificial Intelligence is pretty new in Market and they are very fake gurus in this field who do not know how to train the data and get the desired results. Anyway, we choose the location which has most frequent complaints on slow service (Yes, we figured it out from Google Reviews duhh!). At that location kitchen staff produces more burgers, fries and chicken in rush hours and when the demands cuts wastage occurs and cost rises.

This location experience high employee turns over specially the Chefs because they have the huge burden to cope up with the running demand and cut down the wastage. Management spends huge sum of money on employee trainings but do not able to cut down the waste but in-fact they end up hiring inefficient employees which speeds up the waste process.

SOLUTION

Hitech Provider starts gathering data based on the sensor suite they deployed in the kitchen. Other data set of customers have been received through cameras of Lobby and outside of the restaurant and in drive through.

In order to get the best result for this location and to predict the accurate demand, we need to process one-year historical POS data from which a real-time customer demand prediction model was trained. The current data which we got through the kitchen sensor and through security cameras of the lobby and on the drive-thru was integrated with the new POS System so our trained model could continuously improve in real-time by using the past and current data from the Restaurant.

The high employee turnover can be reduced if they were given accurate demand information beforehand. As orders from POS or predictions from our trained model were generated it is simultaneously displayed on their kitchen screens instructing them how much they need to prepare in a given time. Coordinating with the kitchen crew and the demand of customers helps in intelligent batching which allows them to prepare larger batches of food less frequently and enables them to perform additional tasks like the preparation of the Salads and fries.

RESULTS

Service speed has increased by 25 %. Kitchen efficiency saw a huge jump to 55%

The results were very phenomenal. After the initial deployment of Artificial Intelligence and Machine learning we managed to increase the service speed by staggering 25% during the peak hours. Our Trained model tracked astonishingly close to actual number of Orders received by the restraint. The following Chart show the comparison of service time before and after the installation.

- Before

- After

CHART 1: Comparison of Service Times Before and After Installation

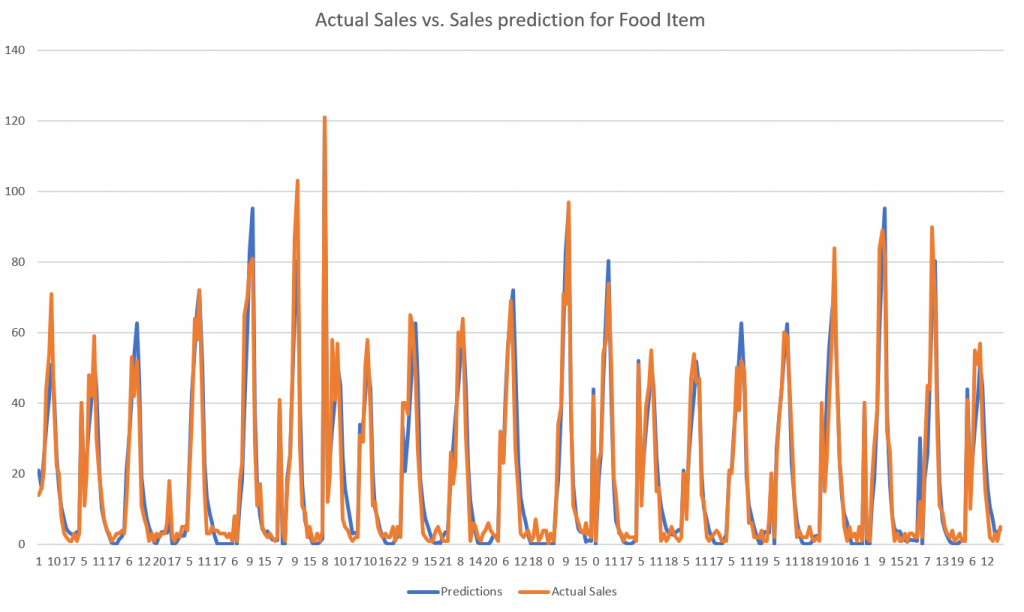

Now, see this Second Chart where Actual and predicted sales have been compared.

CHART 2: Comparison of hourly AI Predictions vs actual hourly sales for January 2021

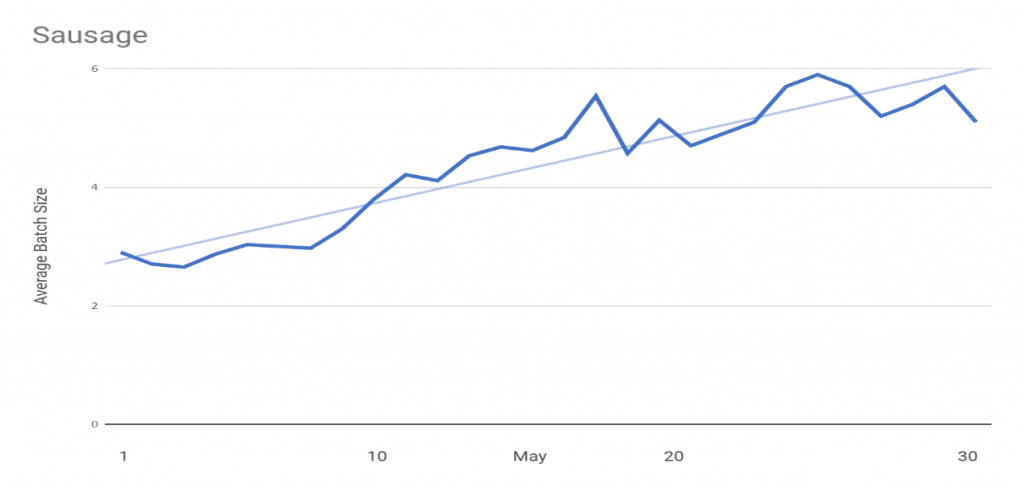

After the deployment of our AI and ML model the training of the kitchen staff became a piece of cake for the Managers because they just tell them the fix pattern which they have to follow and in return the waste reduced significantly and the overall efficiency of the kitchen rose to 55 %. See the third chart below.

CHART 3: Average daily batch sizes As of February 15 2021

CONCLUSION

With the help of Advanced technology like Machine Learning and Artificial Intelligence, we can accurately predict the demand at a restaurant. The best part of these models is that they continuously learn and update themselves at each location from the moment of their installment. This is the era of technology and it is the best time to shift from orthodox methods to advanced ML and AI technology. Beat your Competitors before they beat you. Hire Hi-tech-Provider and book a free consultation to know how your restaurant can be transformed.